Practical Applications of Smart Breakers in Modern Home Construction

Practical Applications of Smart Breakers in Modern Home Construction In an era of smart technology, the modern home is evolving, integrating systems that enhance efficiency,

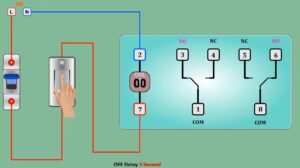

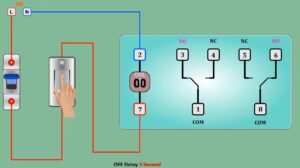

In the world of automation and control systems, timing is everything. The precise control of when a device or system shuts down can be just as critical as its performance during operation. This is where the off delay timer relay comes into play—an essential device in a vast array of industries. Through advanced timing technology, these relays provide the necessary control to shut down systems or equipment after a preset time delay following a signal, offering an extra layer of precision and reliability to operations.

An off delay timer relay functions by initiating a countdown when a control signal is turned off. Only after the delay time elapses does the relay cut power to the equipment, ensuring any additional processes or safety protocols have time to complete before the system shuts down. This delay element is adjustable and can be fine-tuned to the specific needs of the application, whether it’s seconds, minutes, or hours, providing an invaluable utility in customizing operational sequences.

One can find off delay timer relays across all corners of the commercial and industrial realms. From managing the orderly shutdown of a motor to controlling the lighting in buildings to maximize energy efficiency, the applications of off delay timer relays are as diverse as they are significant. As automation continues to weave into the fabric of industrial processes, the role of these timing devices becomes increasingly pivotal, safeguarding and enhancing the performance of complex systems.

Understanding how these

The primary function of a relay module is to switch electrical devices or systems on and off. It also serves to isolate control circuits, ensuring that low-power devices, such as microcontrollers, can safely control higher voltages and currents. This capability is particularly beneficial in scenarios where a small control signal from a microcontroller needs to switch higher currents. In essence, a relay module amplifies this control signal, enabling it to manage more substantial electrical loads.

It’s essential to differentiate between a relay and a relay module. While a relay is a single device comprising an electromagnet and a switch, a relay module encompasses multiple relays and additional components. These extra components provide added layers of isolation and protection, ensuring the module’s safe and efficient operation.

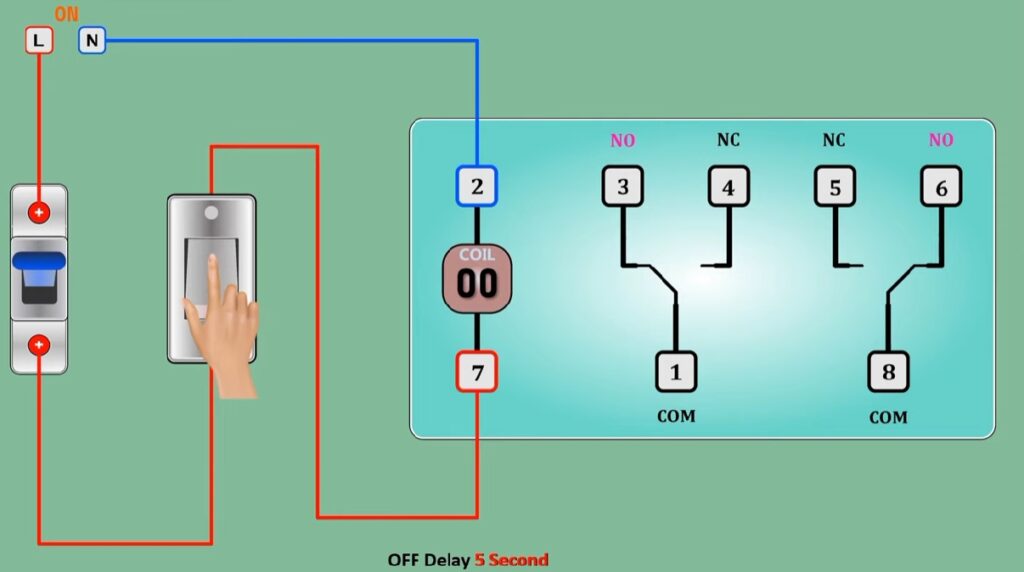

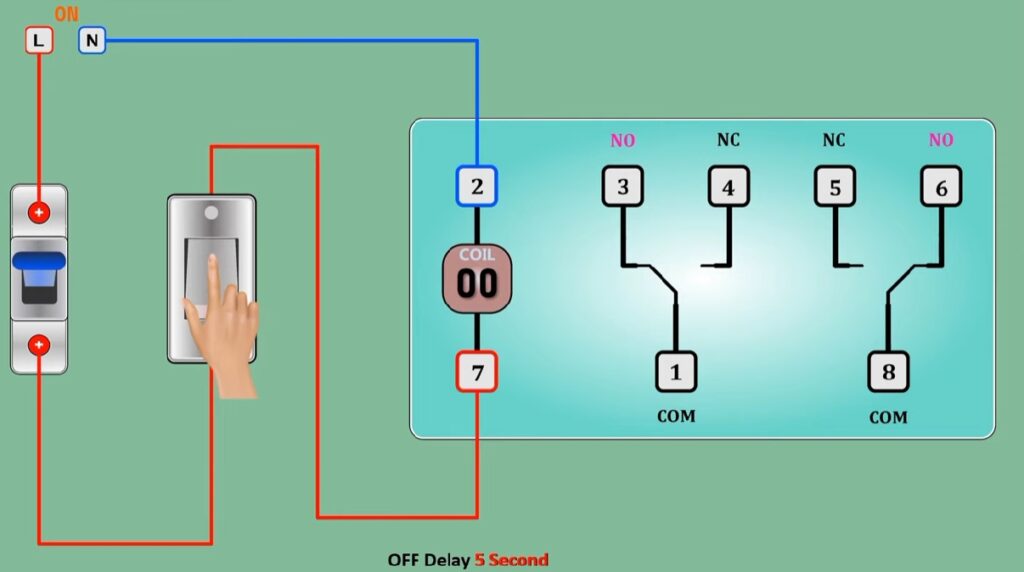

how the relay timer works off delay

Off delay timer relays serve a crucial role in various applications, ensuring that a circuit remains powered for a predetermined period after the control switch has been turned off. Here’s how they work:

Mechanism of Operation:An off delay timer relay includes a control switch and a timing mechanism. When you turn on the control switch, the relay allows current to flow immediately. However, the real magic happens when you turn the switch off. Instead of cutting power right away, the relay starts its countdown based on the preset time delay. Once the time elapses, the relay opens and finally stops the flow of current to the circuit.

Components and Circuitry:The heart of an off delay timer relay is the timing circuit, which typically includes a capacitor and a resistor. When the switch is turned off, the capacitor begins to discharge slowly through the resistor. This discharge period is what creates the delay. The relay itself is an electromechanical switch, which may consist of coils, an armature, contacts, and springs.

These components work together to maintain the current flow after the control switch is off and until the timing mechanism concludes. You can adjust the time delay by changing the values of the capacitor and resistor, which gives flexibility to suit different needs and applications.

In summary, off delay timer relays are invaluable for processes that require a period of continued operation after switching off. With an understanding of their mechanism and components, you can better integrate and troubleshoot these devices in your systems.

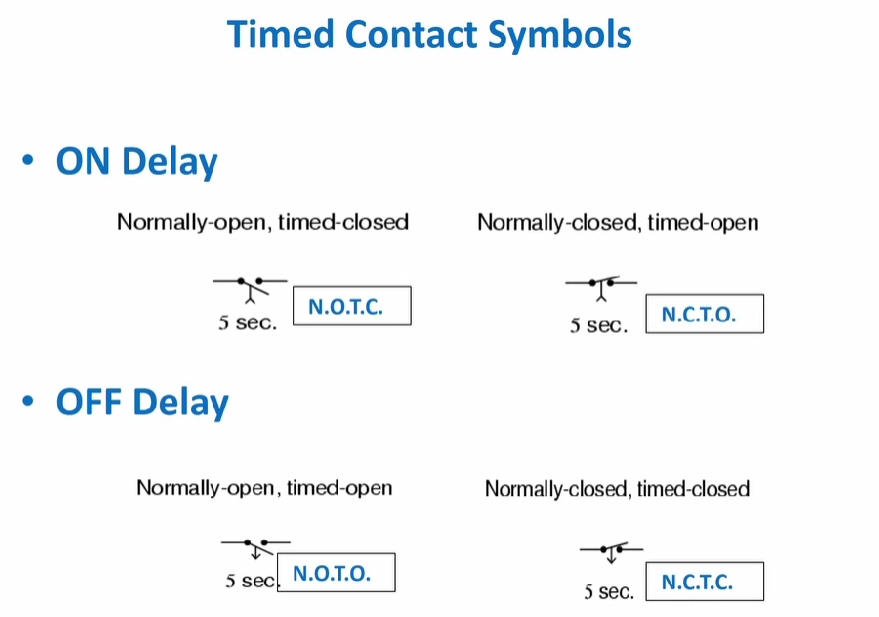

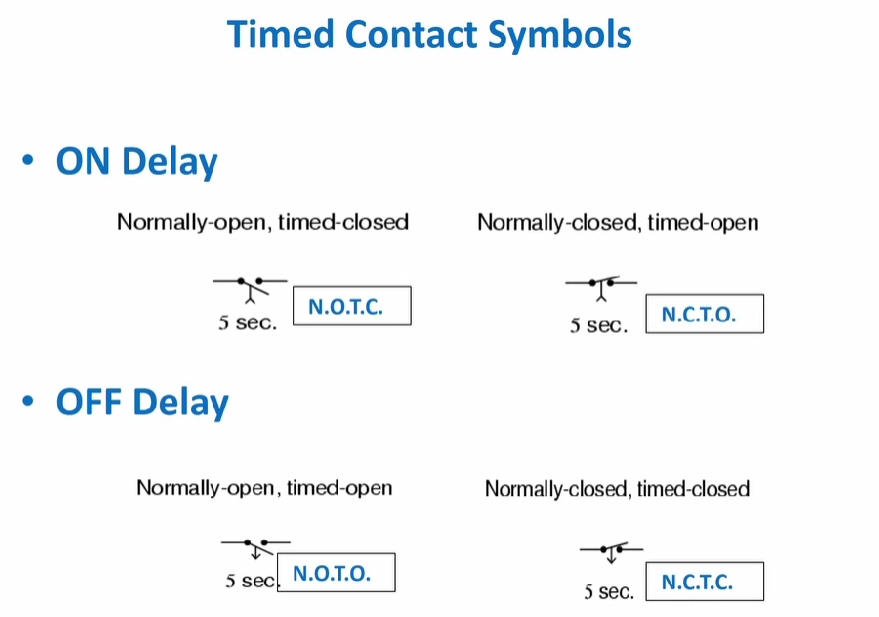

The synchronization of events in automation depends significantly on the timing relays used in controlling electrical circuits. Primarily, there are two types of timer relays: off delay relays and on delay relays. Each serves a unique function, playing a key role in various industrial or commercial settings.

off delay and on delay

Off Delay Timer Relays:The off delay timer relay, also known as a delay-on-break relay, keeps the circuit closed for a specific time after the power is turned off. This relay will only open and stop the flow of electricity after the set delay time has passed following the interruption of the controlling switch.

On Delay Timer Relays:Contrastingly, the on delay timer, also known as a delay-on-make relay, functions in the opposite manner. When power is applied to the control switch, this relay starts a timer. Only after the predetermined delay time elapses does the relay close the circuit, allowing electricity to flow.

Distinct Uses in Scenarios:To illustrate, let’s consider an industrial conveyor system. An off delay timer relay could be used to allow a few extra seconds of run time after the off switch is engaged, ensuring all items have cleared off the conveyor before it comes to a full stop. This is particularly useful for safety or process completion.

On the other hand, an on delay timer relay would be suited for a scenario where machinery should only start operating after a warm-up period once switched on, such as heating systems that require a steady temperature before commencing operations.

Ultimately, the choice between an off delay and on delay timer relay depends on the specific requirements of the process or application and which sequence of events is most beneficial for the task at hand.

Off delay timer relays are integral in managing operations across various sectors. They excel in applications that necessitate a controlled continuation of power after an initial signal has stopped. Let’s explore the implications of these devices in industrial settings and their utility in commercial environments, especially concerning lighting systems.

Industrial Efficacy:In the industrial sphere, off delay timer relays are fundamental to maintaining a harmonious workflow. Consider a production line scenario where multiple stages are involved. An off delay timer permits the machinery to operate for a designated period post-command, ensuring that the ongoing task is completed before shutdown, thus mitigating interruption risks. This not only elevates efficiency but also boasts benefits regarding operational safety.

For instance, emergency ventilation systems in factories may rely on off delay timers to guarantee that harmful fumes are expelled thoroughly before the fans turn off. Similarly, these relays are crucial for complex machinery that requires a cool-down phase to prevent overheating after use, allowing them to run cooling cycles appropriately.

Sustainable Commercial Integration: Lighting SolutionsTransitioning to commercial utilities, off delay timer relays prove invaluable in energy conservation and operational management. Lighting, for instance, is an area where these timers can significantly affect energy usage. By ensuring lights remain on only for the necessary duration after work hours, for example, businesses can slash electricity costs considerably.

This is particularly beneficial in spaces such as malls or office buildings where ample lighting is essential during operating hours, but not so much after closure. Here, off delay timers can manage illumination, ensuring that lighting remains active for cleaning crews or security measures and then systematically shutting down to preserve energy.

Ultimately, the strategic implementation of off delay timer relays can streamline industrial processes for maximum productivity and imbue commercial practices with energy-efficient methods. Their ability to judiciously manage power supply post-activity stands as a testament to their functionality and underscores their significance in contemporary automation systems.

Incorporating off delay timer relays into automation setups brings a new level of precision and reliability. These devices are critical for ensuring efficient operations without sacrificing safety or control. In this section, we’ll explore how off delay timer relays can be assimilated into automated systems and discuss examples that underscore their value in enhancing industrial and commercial processes.

Automated systems are all about optimizing efficiency and workflow. Off delay timer relays contribute to this by managing the deactivation timing of machinery and equipment. For instance, in automated assembly lines, an off delay timer can ensure that robotic arms and conveyors work in perfect unison. After an arm completes a task, such as welding or assembly, the relay can delay the shutdown of the conveyor, ensuring the next piece is in place before the arm reactivates, streamlining the process without human intervention.

Safety is another paramount concern in automated environments. Off delay timer relays can be used in safety systems to maintain functional emergency lighting, power to critical safety devices, or alarm systems for a set period after a power loss, ensuring individuals have time to safely evacuate a facility or complete essential tasks.

Control and accuracy are also where these relays shine. In precision agriculture, for instance, systems rely on timers to precisely regulate water or nutrient supply. An off delay timer relay could keep irrigation systems running for a short period after sensors indicate adequate moisture levels have been reached. This ensures thorough absorption and prevents waste, thus enhancing crop management and sustainability efforts.

Integrating off delay timer relays into these automated systems not only optimizes operational sequences but also fortifies them against abrupt changes, ensuring continuity, maintaining safety standards, and enhancing the precision of controlled processes. They become silent yet essential conductors in the symphony of automation, orchestrating the timings of activation and deactivation to perfection.

Managing electrical circuits efficiently requires the careful selection and installation of components like the off delay timer relay, which continues to power a circuit for a set time after being turned off. To ensure your system’s optimal performance, it’s crucial to choose the right relay and install it correctly. Below is a guide to assist you in these essential steps.

Understand Your Requirements: Determine the time delay range, system voltage, and current handling requirements for your application.

Check Compatibility: Ensure the relay’s technical specifications align with your system’s needs, including control voltage, load current capability, and time delay settings.

Consider the Environment: If the relay will operate in demanding conditions, select one with adequate protection against dust, moisture, and temperature fluctuations.

Quality and Certifications: Choose a relay from a trusted manufacturer with the relevant certifications for your region or sector.

Turn Off Power: Disconnect power before beginning installation to avoid any safety hazards.

Follow the Manual: Adhere to the manufacturer’s wiring diagram to correctly connect the relay.

Secure Connections: Make sure all electrical connections are firm to prevent potential failures.

Mount Properly: Position the relay as intended by its design, which might require vertical mounting for heat dispersion.

Test Before Use: Once installed, test the relay with the circuit powered to verify it functions within the desired time delay.

Regular Maintenance: Routinely inspect the relay and its connections to maintain consistent operation and longevity.

By following this guidance to select and install the right off delay timer relay, you set the stage for smooth and efficient operation of your electrical systems.

Verify Time Settings: Ensure that the time delay settings are properly calibrated for the specific application.

Calibrate the Timer: Time the off delay period with a stopwatch to see if it corresponds with the set duration. Make adjustments if discrepancies are found.

Assess Ambient Conditions: Extreme temperatures can affect the timing mechanism. Ensure that the relay operates within its recommended temperature limits.

Fuse Inspection: Look for a blown fuse and replace it if necessary, making sure to match the correct amperage.

Test Relay Coil: Check the coil’s resistance with a multimeter to determine if it falls within the expected range.

Check for Visible Damage: Inspect the relay for any signs of overheating, cracks, or other physical damage that might necessitate replacement.

Wrapping up our comprehensive look at off delay timer relays, we’ve delved into their function, significance in industrial and commercial applications, installation, troubleshooting, and maintenance. These devices are integral to various systems, providing controlled power-off sequences for machinery and equipment, ensuring safer operation, and aiding in energy conservation.

The off delay timer relay may be a small component, but its impact on the efficiency and functionality of automated systems is substantial. From controlling the conveyor belts in a manufacturing plant to managing the lights in a commercial building or the safety measures in a facility, these relays are crucial for a multitude of timed processes.

Proper selection, installation, and maintenance are key to the longevity and reliability of these relays. By understanding and applying the knowledge shared in this article, one can ensure that their systems operate at peak performance with minimal downtime.

Whether you are a seasoned technician or a newcomer to the world of automation, the off delay timer relay is a component that deserves attention and understanding due to its vast applications and importance.

By following the guidelines outlined for troubleshooting and proactive maintenance, you will be better equipped to handle any situation that arises, ensuring that your operations remain uninterrupted and efficient.

Remember, the most successful systems are those that are well-understood and meticulously cared for. The off delay timer relay is undeniably a small piece of that larger puzzle, but one that holds the power to significantly alter the outcome of your automated processes.

Practical Applications of Smart Breakers in Modern Home Construction In an era of smart technology, the modern home is evolving, integrating systems that enhance efficiency,

Mastering Time Control: The Essential Guide to Off Delay Timer Relays in Automation Introduction to Off Delay Timer Relays In the world of automation and

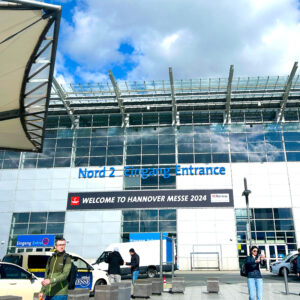

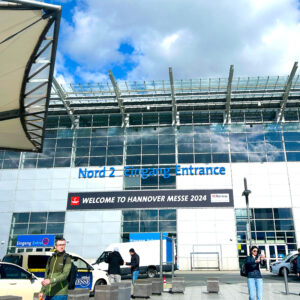

A Triumphant Conclusion at Hannover Messe 2024! DATE:22-26,April,2024 BOOTH:F40-20 A Triumphant Conclusion at Hannover Messe 2024! The Hannover Messe is recognized as the world’s largest

The Ultimate Guide to Upgrading Your Home Electrical Panel with Circuit Breakers Navigating through the process of upgrading your home electrical panel can be a

Tongou was established in 1993, It takes the high-end low-voltage electrical system solutions experts as the brand positioning, takes solving the pressure and challenges of customers as the responsibility, and creates value for customers.

© 2023 Tongou Electrical. All Rights Reserved.